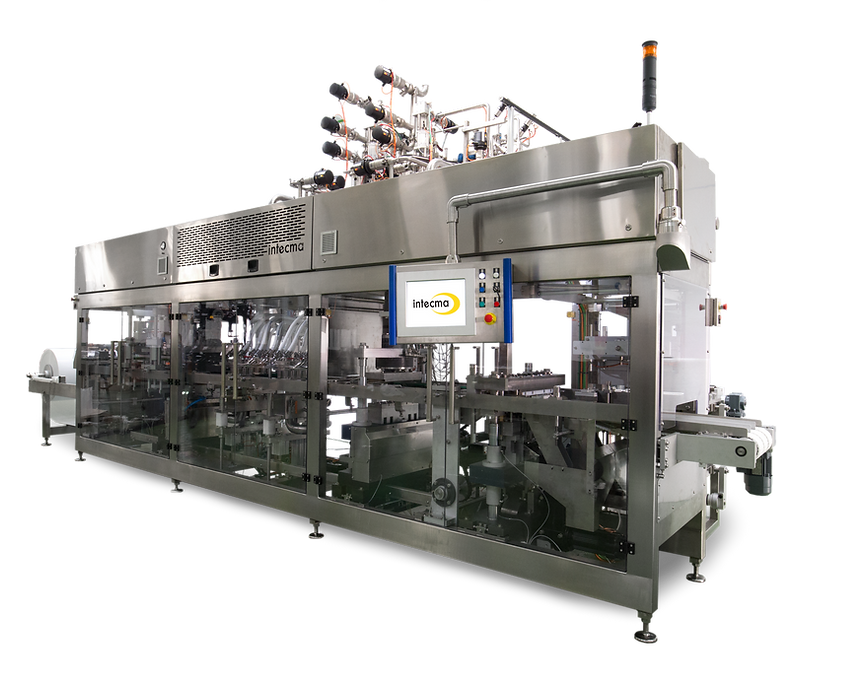

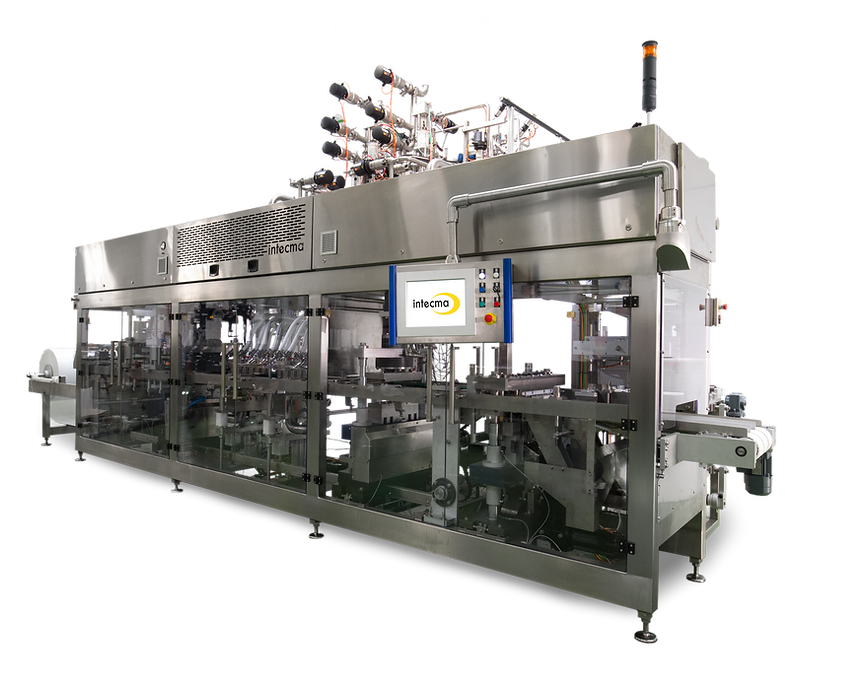

Form Fill & Seal Lines

Features

ZERO Technology

High Output Performance

Easy Maintenance Access

Low Maintenance Costs

New Generation Labelling

Multiple Labe Heights

New Generation Filling System

High Efficiency & Productivity

DTA-800 FILLER

MTA-1200 LABEL

®

Products

MTA Series

Yogurt

Cream Cheese

Desserts

Chocolate

Fruit Puree

Jam

Whipped Cream

SPECIFICATIONS

MTA-1200

2x6

MTA-1600

2x8

MTA-2400

4x6

Industrial Output

Production Output

Plastic Film Pitch

Plastic & Lid Film Width

Plastic Film Thickness

Plastic Materials

Lid Materials

Cup Height

Machine Dimensions

30 cycles/min

21,600 cups/hr

126mm ( 63x63 )

Up to 398mm

0,85mm - 1,2mm

PS - PP - PET

ALU - ALUPET

90mm max

8500 x 4300 x 3500 mm

30 cycles/min

28,800 cups/hr

126mm ( 63x63 )

Up to 524mm

0,85mm - 1,2mm

PS - PP - PET

ALU - ALUPET

90mm max

8500 x 4430 x 3500 mm

30 cycles/min

43,200 cups/hr

126mm

Up to 398mm

0,85mm - 1,2mm

PS - PP - PET

ALU - ALUPET

90mm max

10500 x 4430 x 3500 mm

ZERO Technology Labelling System

®

The key features of this ZERO Technology® labelling system are :

-

Multiple paper heights

-

Automatic tension compensating system of paper banderoles

-

Easy maintenance access of system both in-line and off-line without having to cut the paper banderoles

-

Absence of unnecessary stoppage time for maintenance

ZERO Technology

®

Our unique ZERO Technology® is the result of years of new generation research and development applied to all tools included in an FFS packaging line. Thanks to this technology we will reduce your maintenance costs and increase the performance and life of tools. But most of all, we will streamline and simplify your day to day machine operations.